Every project is unique as to how the panels will be offloaded from the delivery truck. In this case, the only way this custom 13’ panel was going to get to where it needed to go was through the 4th story skylight, diagonally! With only mere inches of clearance on each side, this was a tricky installation.

As you can see, each panel had to be carefully dropped in from above, down the ground floor, nearly 4 stories below. With this being a busy street in San Diego, the installation team did their best to limit crane rental time to one day.

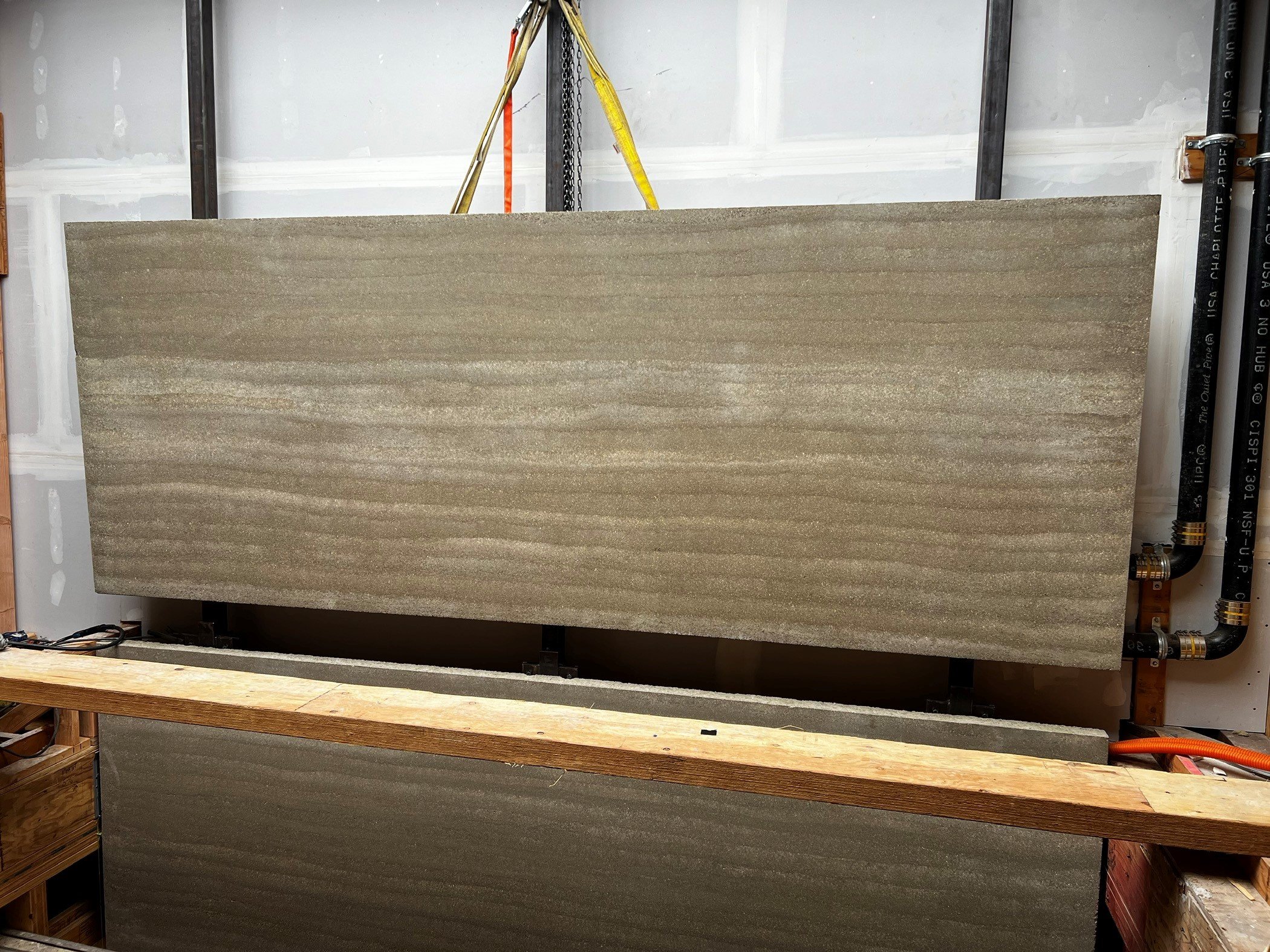

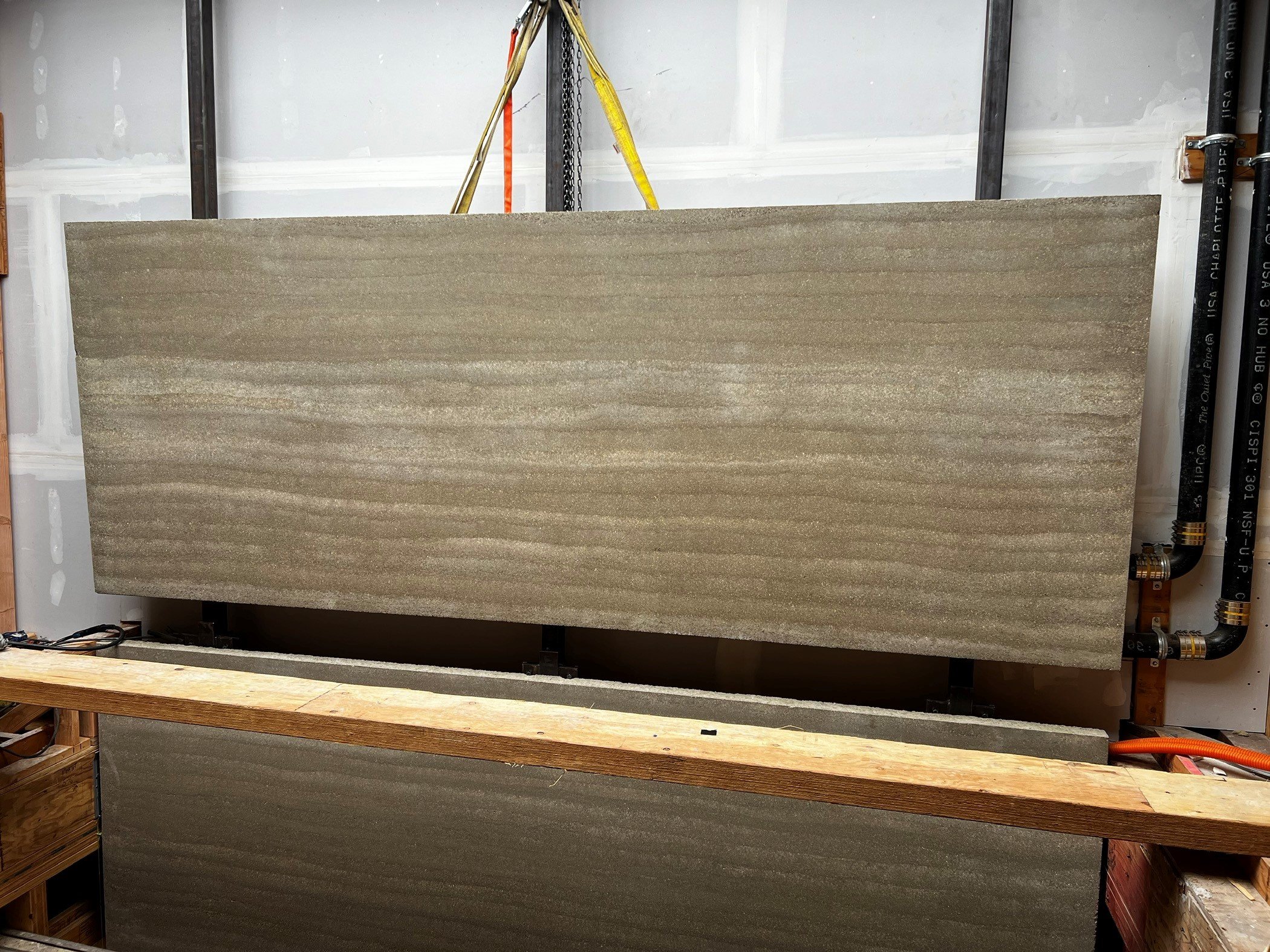

Even though these panels are gray, depending on how the sunlight hits or doesn’t hit them, they will appear to change color depending on the amount of sunlight. In this particular home, this really complemented the sandy beach they were beside.

Though we typically recommend a mitered joint for corners, we can also do a butt joint if desired, for a small return into the wall. This smaller return panel was cut on site from a spare panel.

Because these are panels, you will always be able to see the seamlines vertically and horizontally between panels. This client opted for grouted seamlines (horizontal only). The installation team grouted and then blew in some of the original raw material into the seamlines.